Wood sawdust pellet machines are widely used in Southeast Asia, Europe, Africa and the United States. It can turn waste wood generated during logging or furniture production into high-density fuel pellets, turning waste into treasure.

A sawdust pellet machine is an energy conversion equipment designed to compress wood sawdust that is produced during woodworking into biomass fuel pellets. These fuel pellets typically have a diameter of 6-10 mm and a length of 3-5 cm. With a density ranging from 1.1 to 1.3 grams per cubic centimeter, the wood pellets can be efficiently transported via belt or screw conveyors. As a result, wood sawdust pellets have become a high-quality alternative fuel source in many countries.

Sawdust pellet machines are divided into flat-die pellet mills and ring-die pellet machines according to molds design. Flat-die pellet mills are mainly used for outputs below 1 ton/h, and ring-die pellet machines are mainly used for outputs above 1 ton/h.

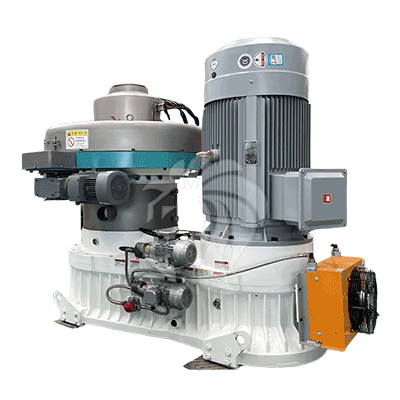

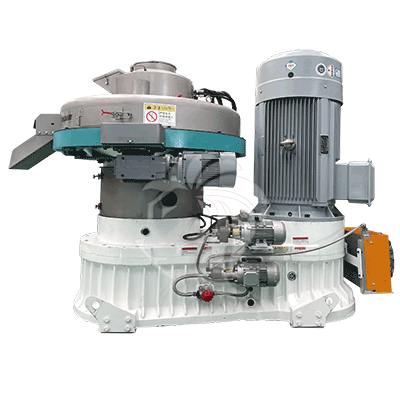

Examine the configuration of the wood sawdust pellet machine carefully. While a high-end configuration alone does not always guarantee stable performance, a pellet machine with an overly basic setup is more likely to experience frequent breakdowns. To ensure reliable 24-hour operation, our wood sawdust pellet machine incorporates top-quality components, including premium brands and designs for the reducer, motor, ring die material, and spindle design.

As a heavy-duty piece of equipment with high energy demands, the quality of the bearings and the design of the lubrication system are critical to ensuring the sawdust pellet mill’s stable operation. Our pellet machine features a dual oil pump lubrication system, and the heavy-duty reducer is equipped with an oil pump for forced lubrication. Additionally, the pressure wheel assembly within the molding chamber is automatically lubricated with high-temperature grease, ensuring a very low failure rate and optimal machine performance.

Ensure that the pellet machine manufacturer has experience working with your specific raw materials. Pellet machines are highly customized, and different materials require unique compression ratios. Even the same raw materials can vary in fiber hardness and toughness depending on the climate in which they are grown, affecting the required compression ratio of the pellet machine’s mold. Choosing an experienced supplier can significantly reduce the trial and error costs associated with pellet production.

There are two key requirements for raw materials used in wood pellet machines:

For many customers, the sawdust size and moisture can up to requests, but there are some wood chips or wood blocks mixed in the raw materials. This is also not acceptable, because it will damage the mold of the sawdust pellet making machine, so it is necessary to use a wood chip drum screener to screen out the wood chips and blocks.

| MODEL | MOTOR | PELLET DIAMETER | CAPACITY |

| KXF200 | 7.5KW | 4MM-8MM | 80-150KG/H |

| KXFD260 | 15KW | 4MM-8MM | 100-200KG/H |

| KXFD300 | 22KW | 4MM-8MM | 200-300KG/H |

| KXFD350 | 30KW | 4MM-8MM | 300-400KG/H |

| KXFD400 | 37KW | 4MM-8MM | 400-600KG/H |

| KXFD450 | 45KW | 4MM-8MM | 500-700KG/H |

| KXFD550A | 55KW | 4MM-8MM | 600-800KG/H |

| KXFD550B | 75KW | 4MM-8MM | 800-1100KG/H |

| KXVRD-560 | 90-132KW | 4MM-8MM | 1000-2000KG/H |

| KXVRD-700 | 160KW | 4MM-8MM | 2000-2500KG/H |

| KXVRD-850 | 220-250KW | 4MM-8MM | 3000-4000KG/H |

When selecting a wood pellet machine, you may often wonder: which type is better?a ring die pellet machine or a flat die pellet machine? The answer depends on your capacity requirements and the characteristics of the raw material fibers. If your output needs are less than 1 ton per hour, a flat die pellet machine is the most suitable option. For outputs exceeding 1 ton per hour, a ring die pellet machine is the better choice.

Now, how do you make decision between a horizontal or vertical ring die pellet machine? Here’s some suggestions:

The price of a wood sawdust pellet machine varies based on the output capacity and model selected. A small homemade sawdust pellet machine starts at around $2,000, while standard industrial models typically range from $20,000 to $30,000. For an exact quote, please feel free to contact us.

Flat die pellet mill and ring die pellet mill each offer distinct advantages. Flat die pellet machines are easy to operate and maintain, but their output is limited to a maximum of 1 ton per hour due to the flat die design, with the die diameter typically not exceeding 560 mm. On the other hand, ring die pellet machines have a more complex design, requiring specialized maintenance training. However, they offer a minimum output of 1 ton per hour, making them ideal for larger wood sawdust pellet production lines.

In addition to the wood sawdust pellet machine, the drum screener is one of the most commonly used pieces of equipment. It efficiently removes larger wood chips and blocks from the sawdust, helping to extend the pellet mill mold’s lifespan and increase the pellet machine’s output. If the raw materials contain a significant amount of large wood chips or blocks, it’s advisable to use a wood hammer mill to process all the material before pelletizing.

Office – A2, Chuangzhigu Zone, Shandong, 256400, China.

86-0533-8680080

info@ecopelletmills.com