we only manufacturing top quality wood pellet press whether it’s a small wood pellet machine or commercial wood pellet mill, as our only goal is to deliver machines with stable operation and a zero-failure rate.

Wood pellet machines have been around for long time, but pellet press for sale with low failure rates, high output, easy maintenance, and consistent & stable operation are still rare in the market. This challenge exists because wood pellet machines require a high degree of customization, along with extensive experience in testing raw materials and operating equipment. The fiber characteristics of the wood directly impact the mold compression ratio, which in turn affects the machine’s output and operating load. We are proud to say that we are one of the most professional and reliable fuel pellet making machine manufacturer you will find.

mini pellet machine

capacity: 80-200kg/h

application: it’s mini pellet press, usually used as a lab pellet press, also for home using.

home wood pellet mill

capacity: 200-400kg/h

application: pellet press machine used or home using or start of a very small business.

small wood pellet press

capacity: 400-600kg/h

application: pellet press machine used in farms, small factories, small pellet production business etc

wood pellet press

capacity: 600-1,100kg/h

application: This press pellet machine is a transitional model used in pellet production lines with high output and low investment.

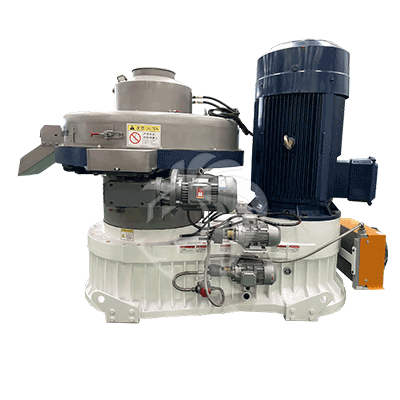

commercial wood pellet press

capacity: 1000-2500kg/h

application: This is the most commonly used pellet mill press in large-scale industrial pellet production because it is the most cost-effective machine.

industrial wood pellet machine

capacity: 3000-4000kg/h

application: This model is mostly used in wood pellet production lines of more than 6 tons/h, and is often used in wood pellet plant with limited workshop area.

Many customers often ask us, “What’s the difference between a flat die pellet machine and a ring die pellet machine? Which one is better?” This question arises because many users have had poor experiences with pellet machines in the past. However, with us, you only need to focus on your desired output. Regardless of the model, we guarantee stable operation. Even our smallest pellet machines come equipped with heavy-duty gear reducers, the same as those used in larger machines. We take full responsibility for the quality, so you simply tell us your output requirements – it’s that easy.

Extensive experience and superior pellet machine configuration.

Trust us—our vast experience will help you avoid the costly trial and error typically associated with customizing pellet machine molds. Our expertise ensures that your pellet machine achieves maximum output efficiency.

24/7 Online Support – Your Most Reliable Service Team.

Many pellet factories operate continuously, 24 hours a day, and during the first three months of production, technical support is often needed. Our technical team is available around the clock, ensuring seamless assistance whenever required, with no time zone limitations.

We communicate sincerely with every customer and only make promises we can deliver.

The stable operation and output of your pellet press mill directly determine the profitability of your pellet project. Our goal is always a win-win outcome, so we care deeply about whether our customers can succeed with the pellet projects. From the very first interaction, we prioritize honest communication and never make promises we can’t keep. So, you can trust us!

Most raw materials, such as wood waste, need to be pre-processed before pelletizing. A common issue we encounter is that the waste wood pieces are quite large, often exceeding 10 cm in diameter, while the customer has chosen a relatively small pellet machine, such as one with a capacity of 100 or 200 kg per hour. Many customers insist on getting a small crusher to match the output of the pellet machine. We understand that many suppliers offer seemingly suitable solutions, but trust us, a very small crusher cannot operate reliably when processing large pieces of wood. It often leads to issues like machine blockages, motor burnout, or blade damage. How do we know this? Many users have shared their bad experiences with us, explaining how they were misled before finding our company.

We have provided pellet solutions to numerous users with various raw materials, and through this process, we’ve grown alongside our customers, gaining valuable experience in processing different materials for pellet production. For newcomers, pellet machines may appear similar, but trust us, the differences in raw materials require distinct adjustments to key components like the reducer and pellet mill die. These differences significantly impact the output of wood pellet machines. Many of our new customers are referrals from satisfied clients, who sought our help to improve their existing machines—some of which had only been in use for three months. While these improvements require considerable time and effort, we’ve successfully increased output by over 20% in many cases. The raw material truly defines the press pellet machine, and when it comes to pellet machines, there is no one-size-fits-all solution.

What are the key factors beginners should consider when press pellet?

That’s a great question. The most common issue novices face is their inability to properly assess the characteristics of their raw materials. If the supplier’s factory is not experienced, this issue often only comes to light during machine testing. It’s crucial to accurately describe whether your raw material is hardwood, softwood, or a mix, as well as the size and moisture content of the sawdust. If these details are uncertain, the best approach is to design molds tailored to different raw materials to minimize testing costs.

When choosing a pellet machine, I’ve come across vertical ring die pellet mill, horizontal ring die pellet mill, and flat die pellet machines. Which one is better for me?

Each type of pellet press wood has its own pros and cons, so your choice should be based on the type of raw materials, production needs, and project budget. If you’re working with a limited budget, a flat die pellet machine is recommended. For high production and 24/7 continuous operation, a vertical ring die pellet machine is ideal due to its automatic lubrication system. If you’re producing feed pellet, a horizontal ring die pellet machine is best because of its high output. Feel free to contact us to discuss your specific needs in more detail.

Do you offer mobile pellet machine or diesel pellet machine?

These two models are custom-made. To ensure machine stability, diesel-powered options are typically available for pellet machines with engines under 50 horsepower, while mobile models are available for machines with power ratings below 37 kilowatts.

Office – A2, Chuangzhigu Zone, Shandong, 256400, China.

86-0533-8680080

info@ecopelletmills.com