Experience premium quality and unmatched efficiency with our homemade wood pellet machine. Perfect for turning biomass into eco-friendly fuel or feed pellets! Get yours today and start making a sustainable difference right from your backyard!

We have received feedback from numerous customers who experienced issues with previously purchased wood pellet machines. Common complaints include the machine overheating and shutting down after just a few hours of operation, clogging when processing hay, or producing insufficient output when making wood pellets. These issues typically stem from design flaws in the pellet machine.

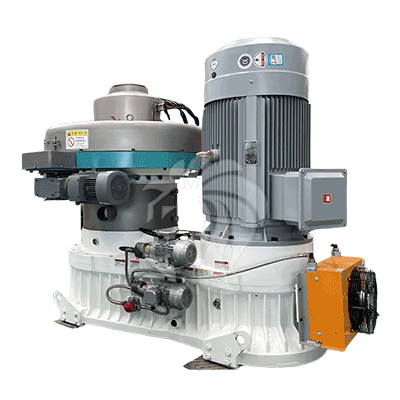

Our home pellet machine, widely chosen by European customers, stands out for its exceptional stability and versatility. It reliably produces feed pellets, biofuel pellets, and fertilizer pellets. All you need to do is replace the mold with one that has the appropriate compression ratio for your material.

Many users mistakenly believe that the primary measure of a small pellet machine’s quality is its energy efficiency. However, this is a misconception. The most critical factor to consider is the machine’s ability to operate reliably, especially challenging ones like grass and sawdust. Insufficient power and excessively high speeds can lead to machine blockages and reduced output, which are common issues with poorly designed models. To address these challenges, our homemade pellet mill are equipped with heavy-duty gearboxes, ensuring stable performance across a range of materials.

The connection method between the main motor and the reduction device in a small homemade wood pellet maker plays a crucial role in determining its reliability during daily operation. Machines with a split assembly design are prone to issues such as oil seal aging and oil leakage over time. If these problems go unnoticed, they can potentially lead to motor burnout. In contrast, our pellet machines feature an innovative integrated connection between the reduction gear and motor, significantly reducing the failure rate and ensuring long-lasting, reliable performance.

Many users focus solely on the purchase price of a pellet machine, overlooking the operational costs. This often results in small pellet machines becoming underutilized, as high maintenance expenses and low production efficiency can significantly increase the overall cost of operation. Our pellet machines address these concerns with a smart design: they are primarily lubricated using engine oil and come equipped with a lubricating oil pump. This system allows the engine oil to be recycled, ensuring low maintenance costs and exceptional cost-efficiency in daily use.

The pellets produced by home wood pellet maker serve a wide range of purposes. Here are the most common applications:

| MODEL | POWER | APPLICATION |

| KXF200 | 7.5KW | home using |

| KXFD260 | 15KW | home using or small farming use |

| KXFD300 | 22KW | home use or small farming use |

| KXFD350 KXFD400 KXFD450 | 30KW/37KW/45KW | small farm use or start from a small pellet business |

| KXFD550A KXFD550B | 55KW/75KW | usually used in a 600-1100kg/h wood pellet production line |

300-400kg/h

small pellet mill for farm us

600-1100kg/h

Flat Die Pellet machine

1000-4000kg/h

Ring Die Pellet machine

Small pellet machines for home use come in two main types: light pellet machines with rotating molds and heavy-duty pellet machines with rotating rollers. The prices vary significantly between the two. A light feed pellet machine typically costs between $300 and $800, while a heavy-duty pellet machine ranges from $1,800 to $2,600.

A small pellet machine with die rotation operates at high speed and features a small press roller assembly, making it suitable primarily for producing feed pellets using grains as raw materials. In contrast, a small pellet machine with press roller rotation operates at a lower speed and has a larger press roller, making it ideal for producing a variety of pellets, including grass feed pellets, wood fuel pellets, and fertilizer pellets.