Insect frass pellets are slow-release fertilizer granules made from high-quality insect feces. The raw materials are insect feces and insect skeletons produced during the breeding process of mealworms or black soldier flies. They contain rich nutrients needed for plants. It is a high-quality fertilizer pellet.

Choosing a fertilizer pellet machine mainly depends on the pellet machine capacity you need. You can use a flat-die pellet machine if you need a small pellet machine. The general output is within 1.5 tons per hour. But if the capacity you need exceeds 1 ton per hour, a ring die pellet machine is a better choice. The same gear reducer is applied for these two models, just the molds are different. The energy consumption and efficiency of the machines are similar.

Flat-Die Type Pellet Mill

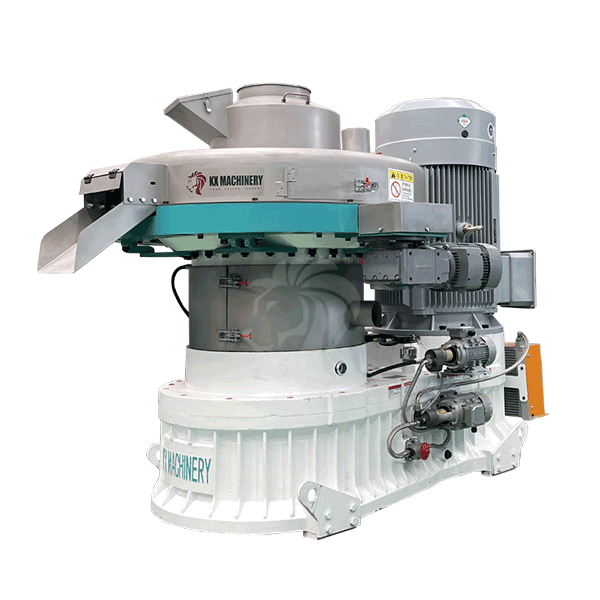

Ring-Die Type Pellet Mill

| TYPES | MOTOR | CAPACITY | APPLICATION |

| flat die type | 7.5kw-75kw | 80kg/h-1500kg/h | small scale factory,farms |

| ring die type | 55kw-250kw | 1000kg/h-5000kg/h | big scale pellet plant factory |

Black soldier fly larvae pellets are a high-quality slow-release fertilizer. During the production process, they are dried and pressed at high temperatures to kill germs. Moreover, this kind of fertilizer pellet can improve the soil structure. Compared with chemical fertilizers, it will not cause soil compaction and is a higher-quality organic slow-release fertilizer.

Under normal circumstances, the minimum pellet diameter of 3-4 mm, but it is recommended to make a diameter of 4-6 mm because it can maximize the pellet-making machine output and extend the service life of the flat die and ring die.

No problem, you can send us your project requirements and we will provide detailed plans and turnkey projects.

No, because the airflow dryer cannot control the inlet air temperature, and has low output and high energy consumption, so it is not recommended.

Office – A2, Chuangzhigu Zone, Shandong, 256400, China.

86-0533-8680080

info@ecopelletmills.com