Converting cow dung into burnable fuel pellets or cow dung fertilizer pellets, avoids pollution and creates additional value. This is a new way to make money.

Cow dung pellet machine is a machine specifized for producing cow dung into dense, uniform pellets. It’s also called cow dung pellet press. Cow dung pellets can be The main components of cow manure include organic matter, nitrogen, phosphorus, potassium and various crude fibers.

The contents of these components vary according to the type of cow and its digestion conditions. Cow dung decomposes slowly, so it can be crushed and dried to make fuel pellets or fertilizer pellets, which can not only improve the environment, but also improve the soil.

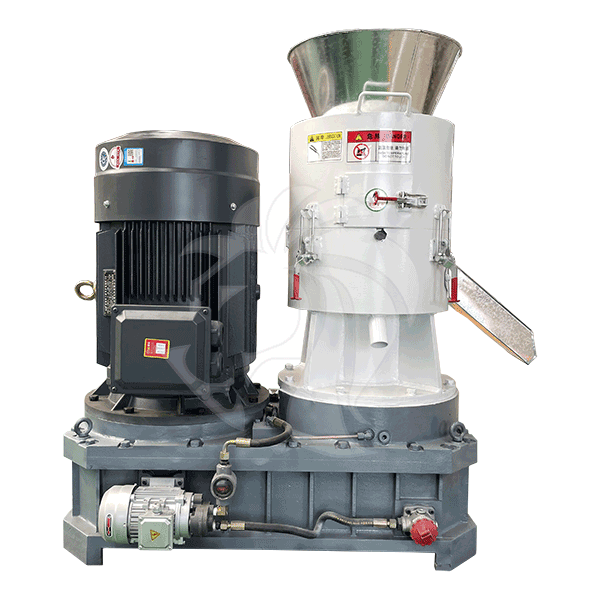

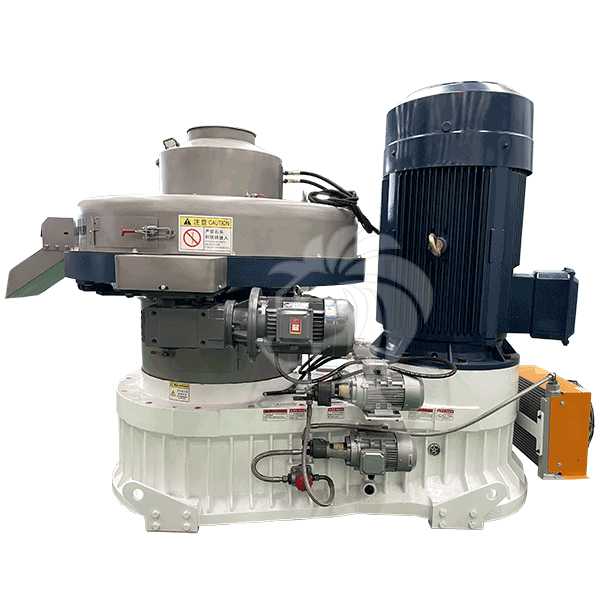

Cow dung pellet making machine mainly include flat-die pellet machines and vertical ring-die pellet machines. They are used in small and medium-sized cow dung treatment projects and large-scale cow dung treatment projects respectively. Cow dung pellet mill is an effective means of resource utilization of cow dung.

80-1000kg/h

Flat-Die Pellet Mill

1000-4000kg/h

Ring-Die Pellet Mill

| MODEL | MOTOR | PELLET DIAMETER | CAPACITY |

| KXF200 | 7.5KW | 3mm-10mm | 80-150kg/h |

| KXFD260 | 15KW | 3mm-10mm | 100-200kg/h |

| KXFD300 | 22KW | 3mm-10mm | 200-300kg/h |

| KXFD350 | 30KW | 3mm-10mm | 300-400kg/h |

| KXFD400 | 37KW | 3mm-10mm | 400-600kg/h |

| KXFD450 | 45KW | 3mm-10mm | 500-700kg/h |

| KXFD550A | 55KW | 3mm-10mm | 600-900kg/h |

| KXFD550B | 75KW | 3mm-10mm | 800-1100kg/h |

| KXVRD560 | 90KW/110KW/132KW | 4mm-10mm | 1000-2000kg/h |

| KXVRD770 | 160KW | 4mm-10mm | 2000-3000kg/h |

| KXVRD850 | 220KW/250KW | 4mm-10mm | 3000-4000kg/h |

Fresh cow dung cannot be directly pressed into pellets because the moisture content is too high and the size does not meet the feeding requirements of the cattle manure pellet plant. Therefore, the following steps are generally required:

1.Collection and dehydration: fresh cow dung moisture content is about 80-90%, and it needs to be collected and dewatering firstly.

2. Drying: using roatry dryer to dry the cow dung moisture content less than 25%.

3. Crushing: crush the cow dung size within 10 mm. The crushed cow dung will have uniform size and the pellets produced with smooth surface, and the pellet machine will have higher output also.

5. Pelletizing: Feed the cow dung into the cow dung granulator and press into pellets, fuel pellets diameter are 6 mm or 8 mm, and fertilizer pellets diameter are generally 4 mm or 5 mm.

6. Cooling packaging: After the pellets are formed, the temperature at about 70 degrees Celsius. If packaging is required, a pellet cooling machine and a packaging machine needed to pack the pellets into 25 kg bags.

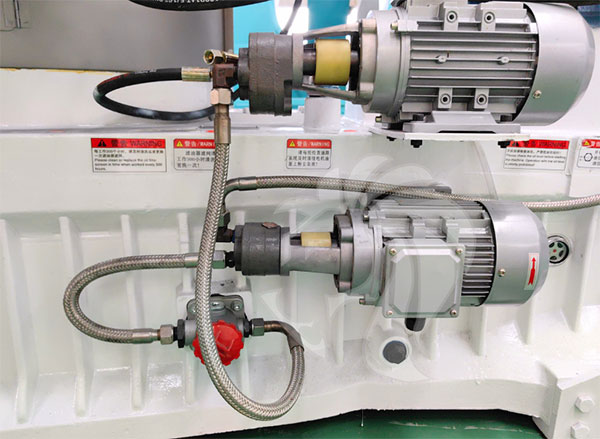

In the process of producing cow dung pellets, according to our experience in many projects, problems are most likely to occur in two sections. First, if you use fresh cow dung as raw material, the water content is very high. During the dewatering process, Because cow manure contains mucus, so need customized dehydration equipment n, otherwise it is easy to effect the dewartering results. Second, cow dung pellets can easily contain soil and sand during the collection process. The cow dung pellet machine needs to customize the ring die and press roller shell , otherwise the service life will be affected during the pellet production process. You can contact us to communicate more details.

If your cattle farm is not large in scale, then we recommend you to use our 37KW or 55KW flat die pellet mill because of its easy maintenance and high output.

Yes, but you need to customize different flat die because the density of fertilizer particles is lower than that of fuel pellets, the output of the pellet mill is also higher when produce fertilizer pellets. Therefore, it is recommended that you can order several flat dies with different compression ratios, so that you can change the molds.

The operation of the two machines is equally stable, but the output is different. The flat die machine has a simpler structure and easier to maintain.

The output and production lines are different, and the price varies greatly. If you only need the smallest pellet machine, the price is about US$2,000.

Office – A2, Chuangzhigu Zone, Shandong, 256400, China.

86-0533-8680080

info@ecopelletmills.com