Commercial wood pellet mill for industrial application, ensuring high efficiency and stable performance. As a professional pellet production line manufacturer, we provide a one-stop waste to energy solution.

Commercial wood pellet machine is widely used in pellet factories, furniture plants, power plants, steam boilers, and sawdust facilities.Large scale wood pellet mill can process various raw materials, including biomass, feed, and fertilizer, etc. The single-machine capacity can up to 1000–4000 KG/H. Full biomass pellet production line is customized based on your raw materials and capacity.

We offer one-stop solutions with more than 12 years of experienced engineers providing on-site guidance for installation and commissioning, along with 24/7 online after-sales support. Wood pellet manufacturing equipment is exported to countries including Ireland, Cyprus, Australia, the UK, Indonesia, India, Kenya, Greece, Kuwait, Dubai, United Arab Emirates, Croatia and Thailand.

The commercial wood pellet mill consists of several key components, including:

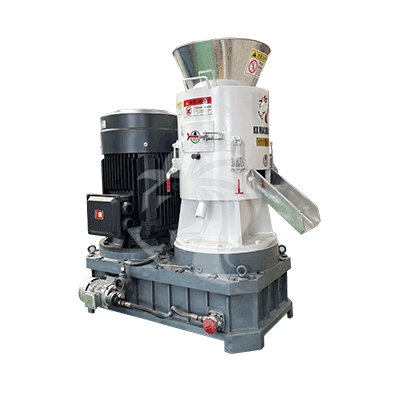

We use the top configuration to make sure stable running and high quality pellets. The whole pellet mill adopts intergrated reducer, three-stage gear reduction, extand the service life. The upgraded biomass pellet machine uses dual oil pump lubrication, providing more comprehensive lubrication and lower failure rate than the traditional single oil pump system.The main motor and reducer are connected by a heavy-duty coupling, which significantly reduces the motor’s failure rate and enhances its durability.

The working principle of the biomass commercial pellet machine is very friendly to the operators. The size of the raw materials within 10MM can be directly made into pellets. They are fed into the pelletizing chamber by the feeding conveyor. Driven by heavy hardened gears, the raw materials are evenly distributed on the inner side of the ring die and extruded under pressure. The vertical effect of gravity enhances energy efficiency, while the dual protection of the cooling and double lubrication systems ensures stable and reliable operation.

For the complete biomass pellet production line, the pellet is transported to the cooler for cooling through a specialized pellet conveyor. To reduce costs, customers can make a pellet silo locally for cooling pellets. Once the temperature drops, the pellets are transferred to the packaging machine for automated packing, helping to save on labor costs and improve overall efficiency.

| MODEL | KX-VRD560A | KX-VRD560B | KX-VRD560C |

| TYPE | Vertical Ring Die | Vertical Ring Die | Vertical Ring Die |

| POWER | 90KW | 110KW | 132KW |

| CAPACITY | 1000-1200KG/H | 1200-1500KG/H | 1500-2000KG/H |

| APPLICATION | Bio-fuel,feed, and fertilizer pellet | Bio-fuel,feed, and fertilizer pellet | Bio-fuel,feed, and fertilizer pellet |

| REMARK | Can customized | Can customized | Can customized |

Biomass wood pellets have a wide range of applications, including boiler combustion, power generation, refineries, steam boilers, farming, home use, fertilizer production, and retail sales. By maximizing resource use and replacing coal and other fuels, biomass pelletizer offer a cleaner energy alternative, making them a key part of future sustainable development and environmental protection.

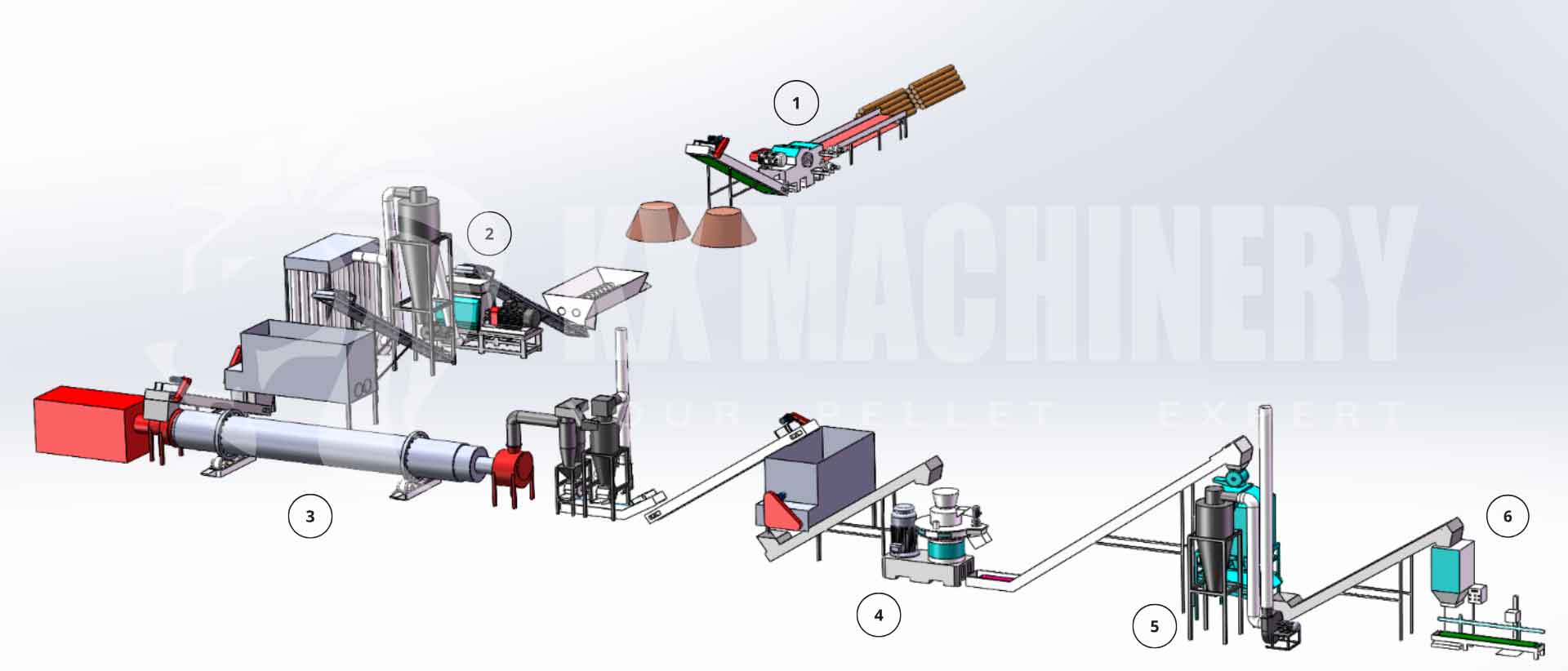

Wood Chipper: ① is Wood Chipping machine, which are designed to efficiently chip large pieces of wood waste, such as wood logs, branches into smaller uniform wood chips. The main features include durable blades, adjustable feed speeds, and advanced safety mechanisms to prevent overloading or clogging.

Wood Crusher: ② is Wood chip hammer mill, it crushing larger raw materials such as wood blocks, wood chips, palm leaves, agriculture waste, etc. into sawdust and smaller sizes, which can reach 3-10mm size through customized inner screens. The wood sawdust crusher is usually equipped with heavy hammers, and the cyclone collects dust system to maintain the best output size and minimum dust generation.

Drum Drying Machine: ③ rotary dryer can dry high-moisture materials, making sure the output moisture content is about 10-20%. It is equipped with adjustable temperature and airflow control devices to adapt to different types of biomass and ensure consistent drying performance.

Biomass Pellet Machine: ④ Bio fuel pellet machine, also known as wood pellet mill machine, it can make various materials into pellets. Such as wood chips, sawdust, agricultural residues, and even waste plastics. These pellets are usually used as fuel for biomass boilers, animal feed, or fertilizer, depending on the material and production requirements.

Cooling and Packing System: ⑤The pellet cooling machine is equipped with a vibrating screen to remove pellet dust, and an ⑥ automated wood pellet packaging system to reduce labor costs, ensuring automation of the wood sawdust pellet production process.

80-150kg/h

300-400kg/h

600-800kg/h

800-1100kg/h

Depends on several factors, including the scale of production, the kinds of raw materials, and the specific equipment, for a simple line, about 90,000USD-130,000USD. If you are getting strat industrial production of wood pellets, the small scale is ok.

There are several factors, such as the ring die and press roller shell gap being too big and not adjusting it in time, or not polishing the hole with sand oil raw material when changing the new ring die, etc.

No need for anything. We can customize the wood pellet production machine for high-quality and high-density pellets.

Usually one year, not including the wear parts. We provide detailed installation and test run support and can promise you that you can run the machine well for the 2-3 days you receive the machines.